Assembly videos

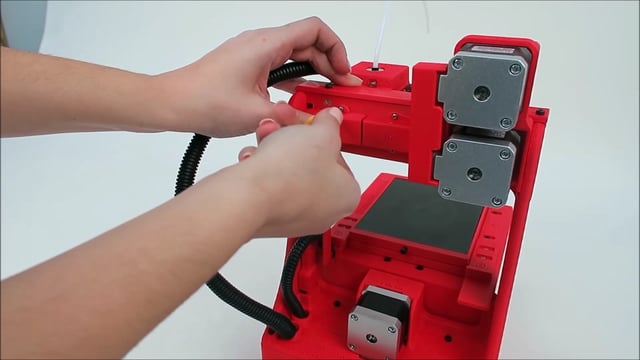

Getting started

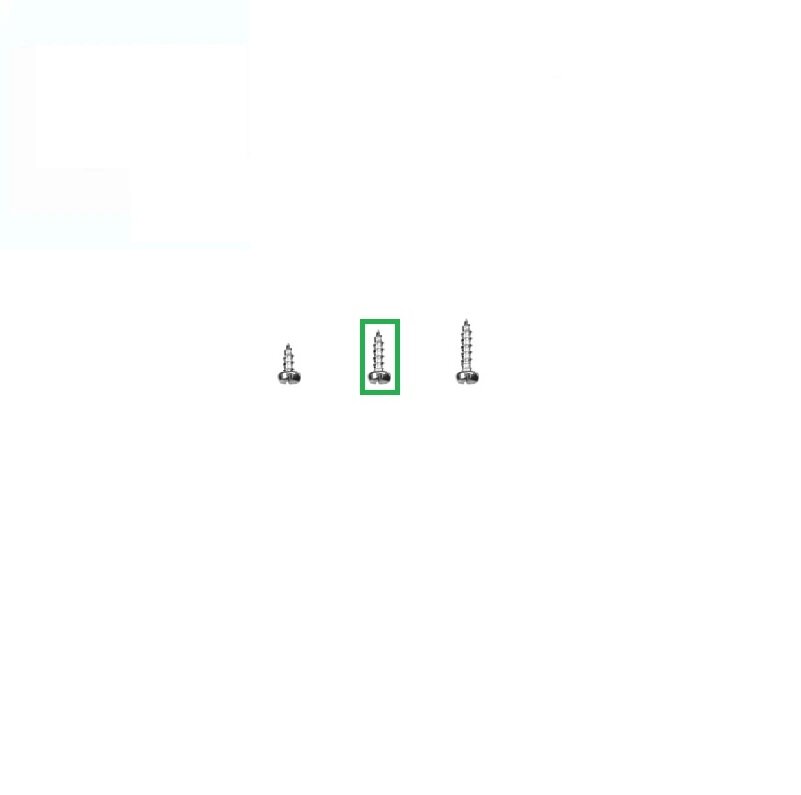

Open your ULIO 3D printer kit, layout all the parts on a flat table and sort the fasteners into small separate containers

In this section you will need to purchase beforehand the following items:

Lubricant: Good quality sewing machine oil meaning non-staining and non-gumming or regular Vaseline

Adult supervision and assistance are required

Begin the assembly

Estimated time: 8 hours

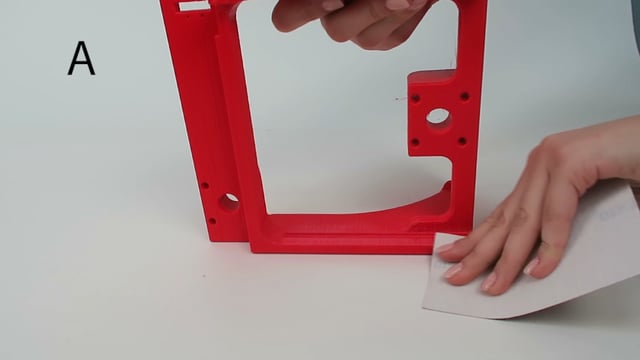

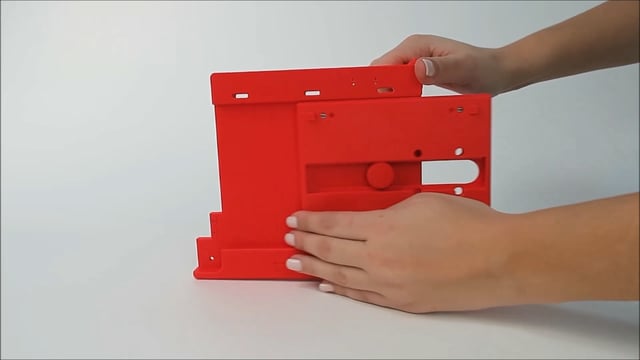

A

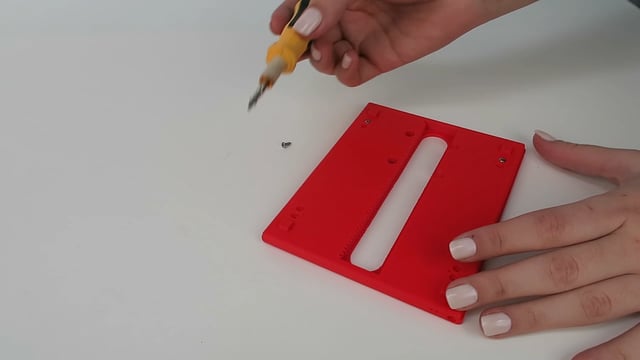

cleaning and Sanding

Clean excess plastic strings within the teeth of the racks, pinions, railings and all openings

All moving parts should slide with ease before assembly, else go back to our STL download page for solutions

B

preparing the gears

Verify if the X, Y and Z gears fit tight onto the motor shaft

If the bore is too small manually drill out a 5 mm hole

c

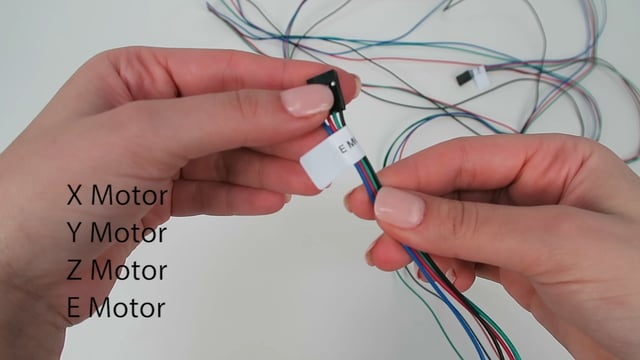

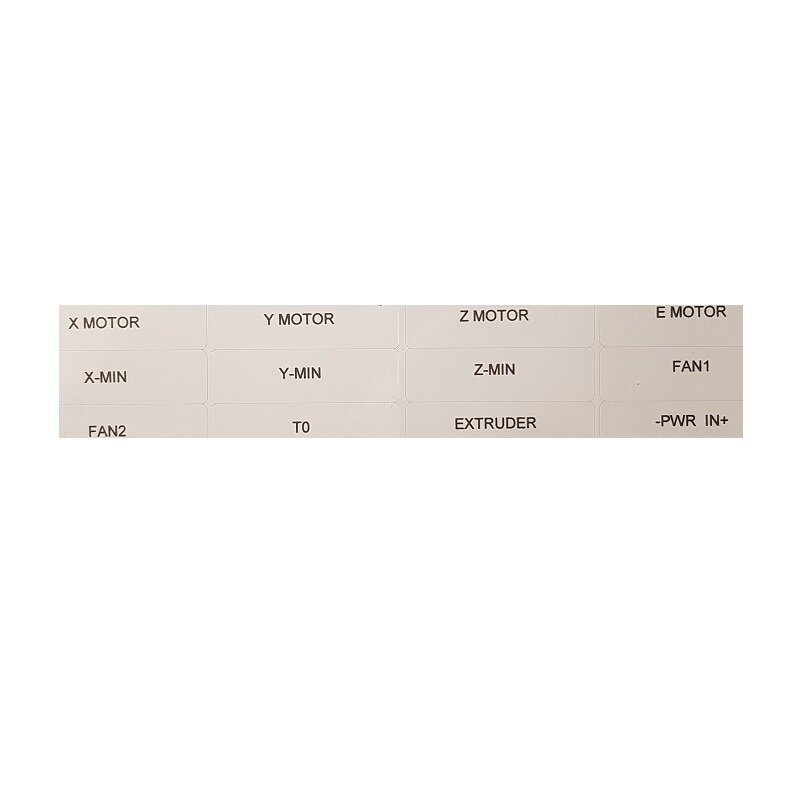

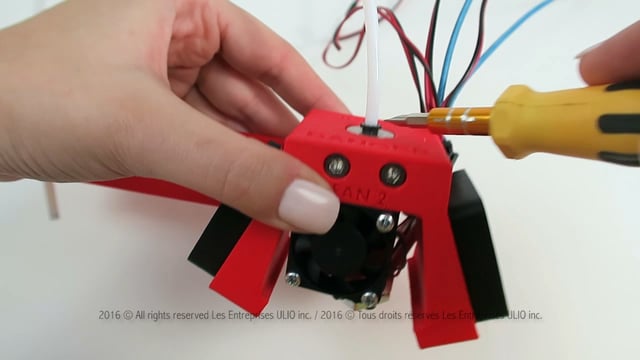

WIRE TagGing

FAN2 and the thermistor T0 have similar wiring connectors

FAN1 tag is not shown in the video

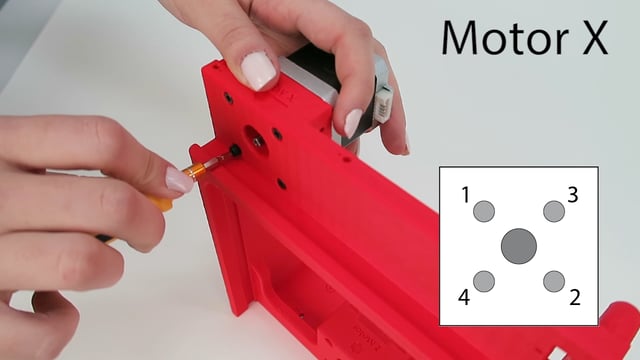

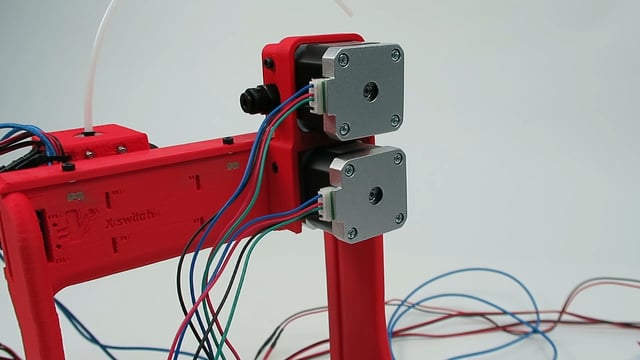

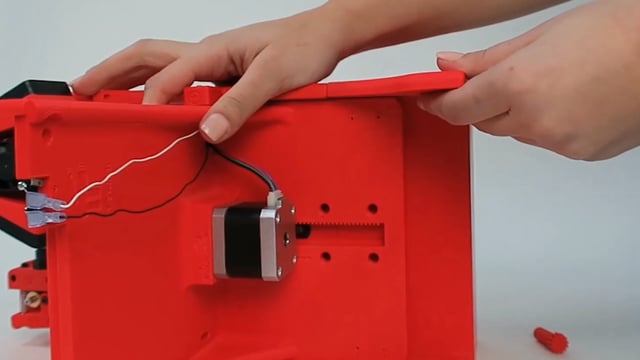

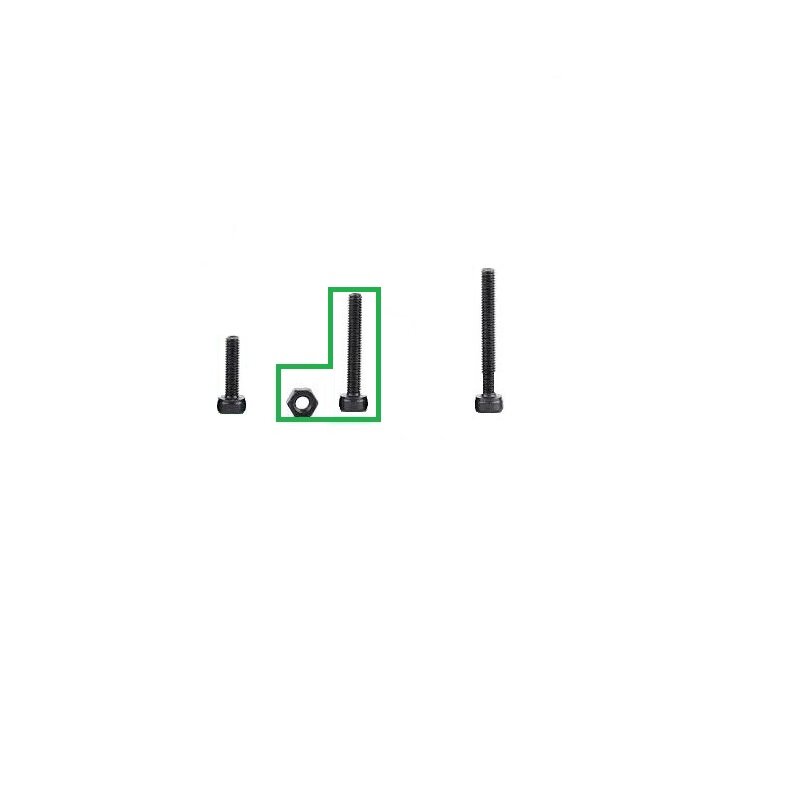

d

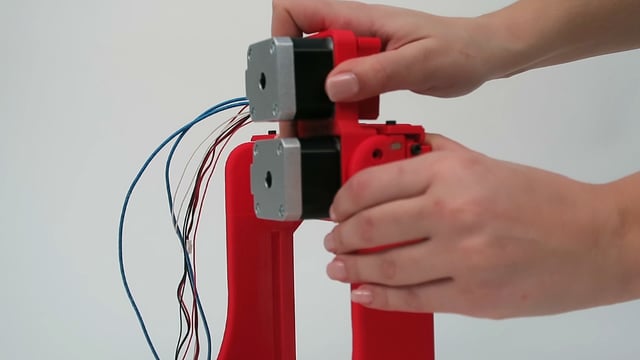

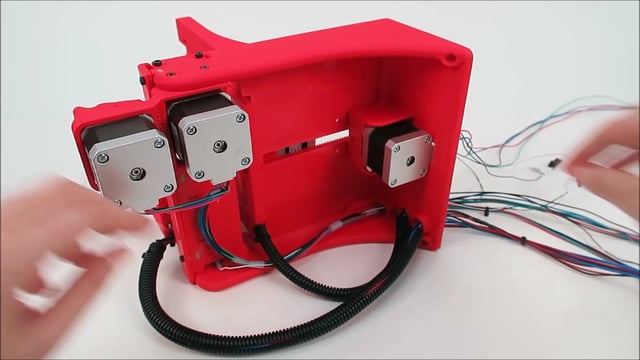

X axis motor

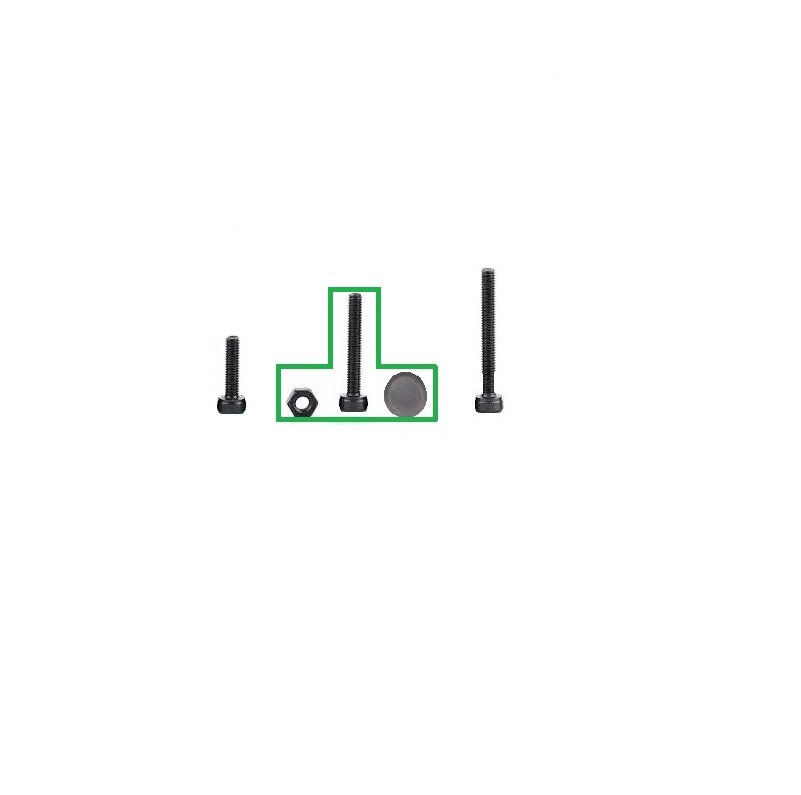

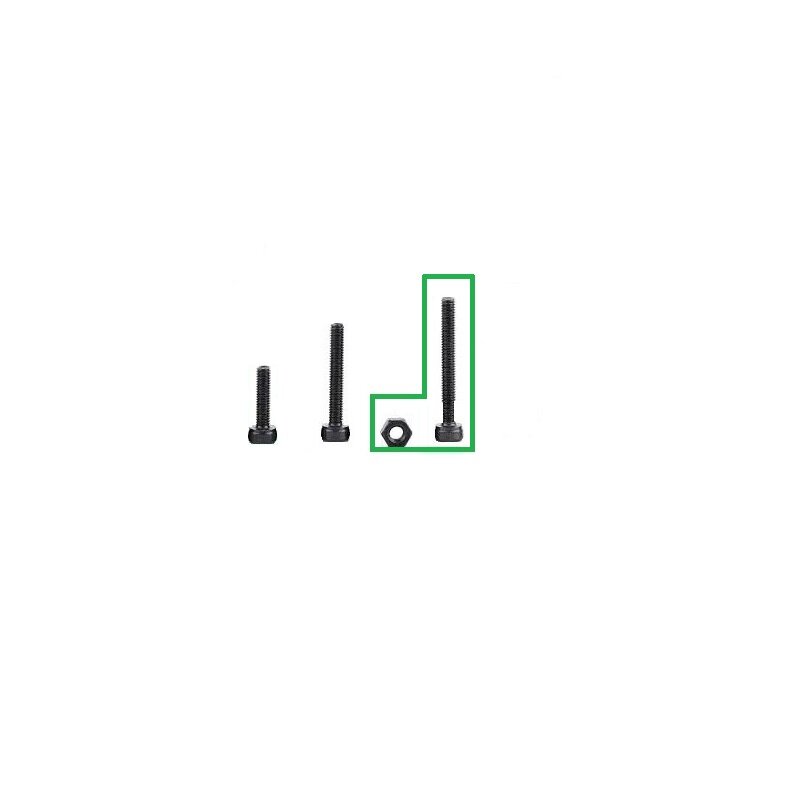

Fasten tight all 4 M3-25 bolts

e

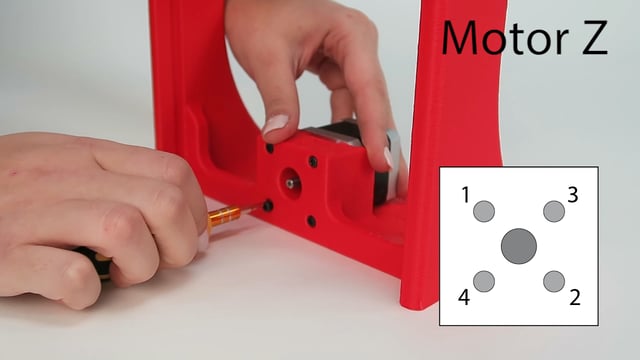

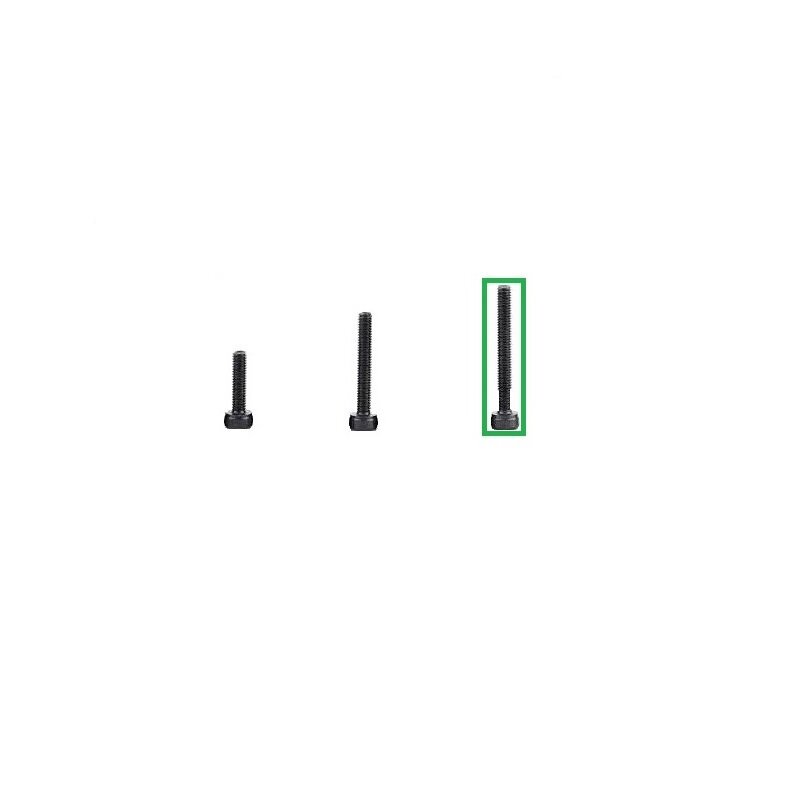

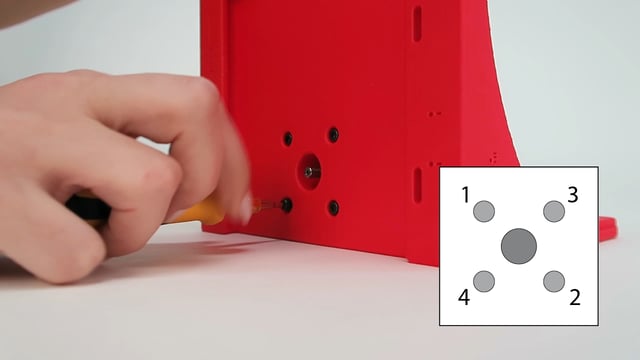

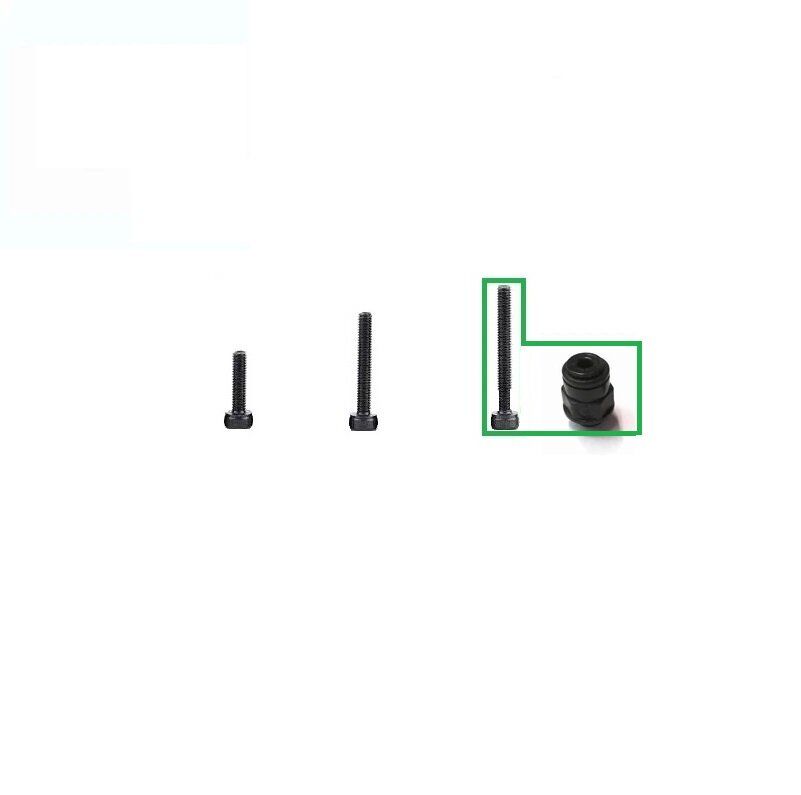

Z axis motor

Fasten tight all 4 M3-25 bolts

f

Y axis motor

Fasten tight all 4 M3-25 bolts

g

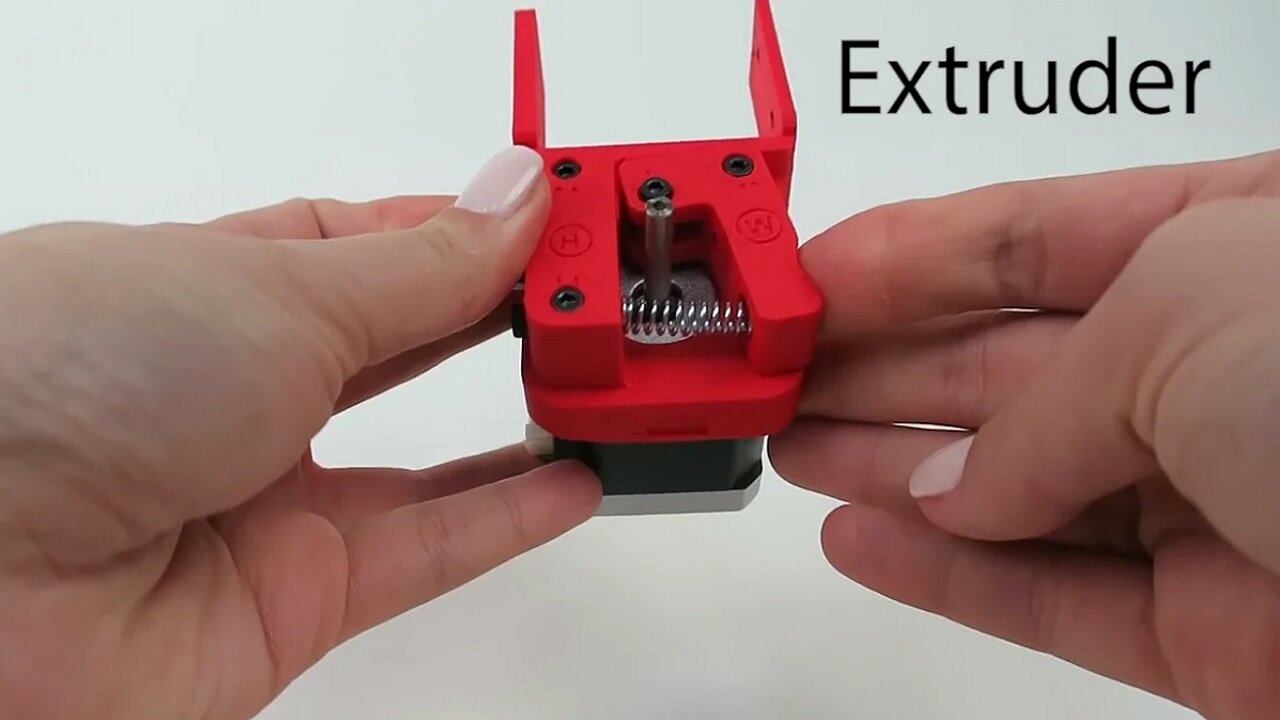

Extruder motor

Fasten tight both M3-20 bolts

h

Extruder assembly (PTFE Coupler)

If the hole is small, sand the inner wall then use a wrench to fasten the coupler tight

i

Extruder assembly (handle)

Make sure the ball bearing is moving freely after assembly

j

Extruder assembly (spring)

k

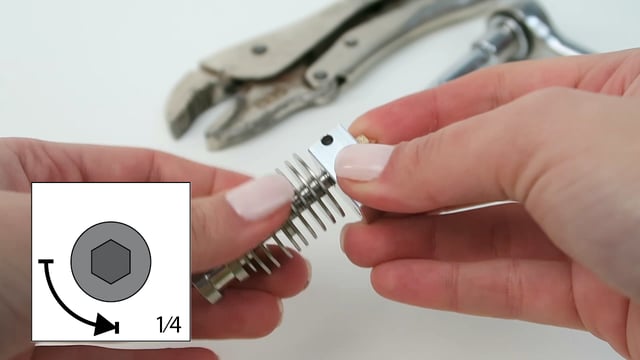

Extruder assembly (hobbed gear)

Align the openings with a 6 in. PLA filament

Tighten properly the set screw on the flat side of the shaft

l

X axis Rack preparation

Insert M3 nuts with the flat sides parallel to the openings

Center the M3 nuts with a small Allen key & a test M3 bolt

Spread plasticine to prevent the M3 nuts from falling out

M

x axis rack and pinion

Install the rack with the teeth at the bottom

Add 2 drops of glue inside the opening of the x axis gear

Align the flat side of the motor shaft with the flat side of the gear, hold the backside of the motor and push in the gear

Do not tap on the the motor, it will damage it

Allow the glue to dry for 5 minutes

To remove the gear, break off the head with pliers, remove the motor, then cut off the rest with cutters

N

x axis rack and pinion adjustment

This step is only required, if you’re having problems moving the X axis rack. Else skip to the next section.

Ease the pressure between the rack & pinion by raising the X axis motor

O

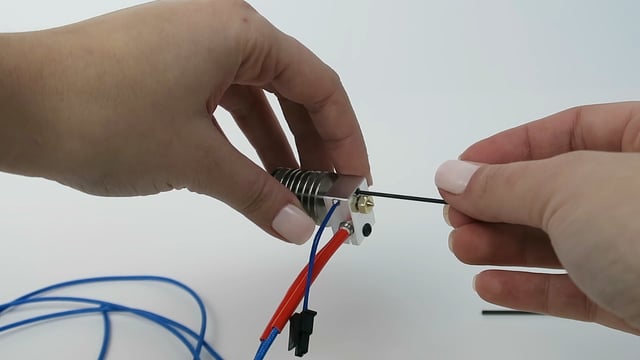

Hotend assembly - part 1

Important notice

At 39 sec. make sure to hold the nozzle with your finger while retightening the heatsink into the heater block

P

Hotend assembly - part 2

Tighten securely the heater cartridge in place (it's normal to see the aluminum block bend a little)

Unlike the heating block, do not over tighten the thermistor screw otherwise you risk permanent damage

Stop tightening as soon as you feel a bit of resistance

Make sure the thermistor does not move

Tie rap the thermistor to the wiring of the heater cartridge

Q

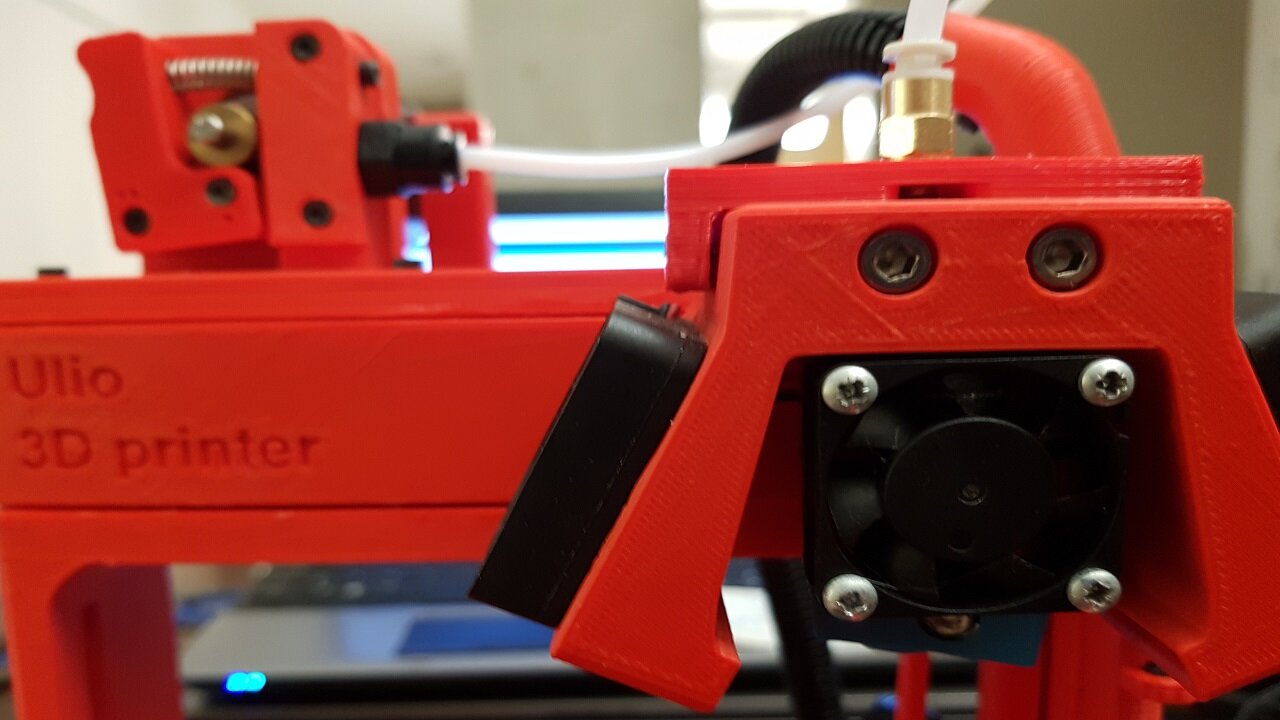

Hotend installation

Unlike what’s shown in the video, turn the hotend so the shorter side of the heater block is facing you

You don’t have to install the M4 nuts if it’s too hard to fasten

R

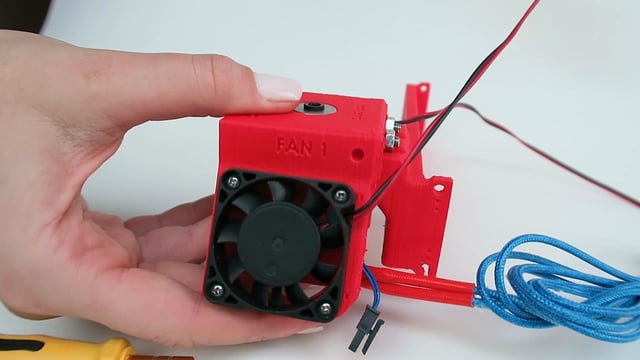

Side cooling fans (FAN1)

Do not hold the fans with the blades

S

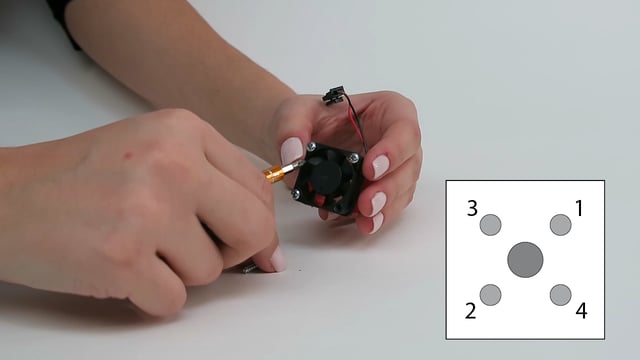

Hotend cooling fan (FAN2)

Do not hold the fans with the blades

The hotend cooling fan (FAN2) might come with long wires

T

Hotend silicone cover

Do not hold the fans with the blades

U

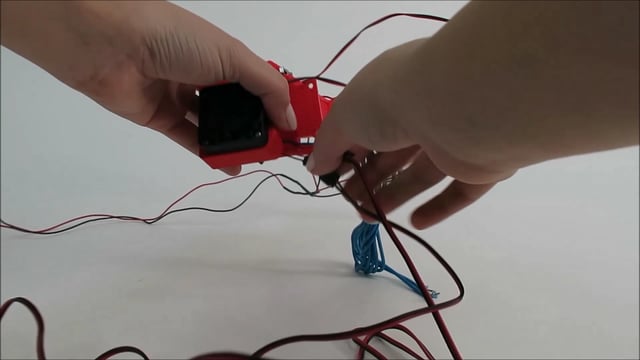

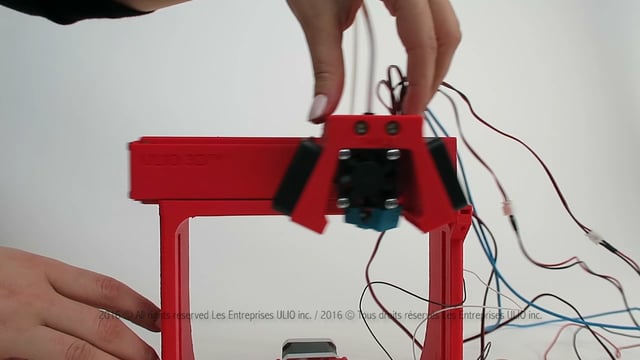

Hotend and faNs wiring

FAN2: The hotend cooling fan might have similar wire connectors to the thermistor (T0)

FAN1: The longer cable connects to the fan on the left while the shorter cable connects to the fan on the right

The attached bundle of wires should not be sticking out or they might restrict movement of the X axis rack

V

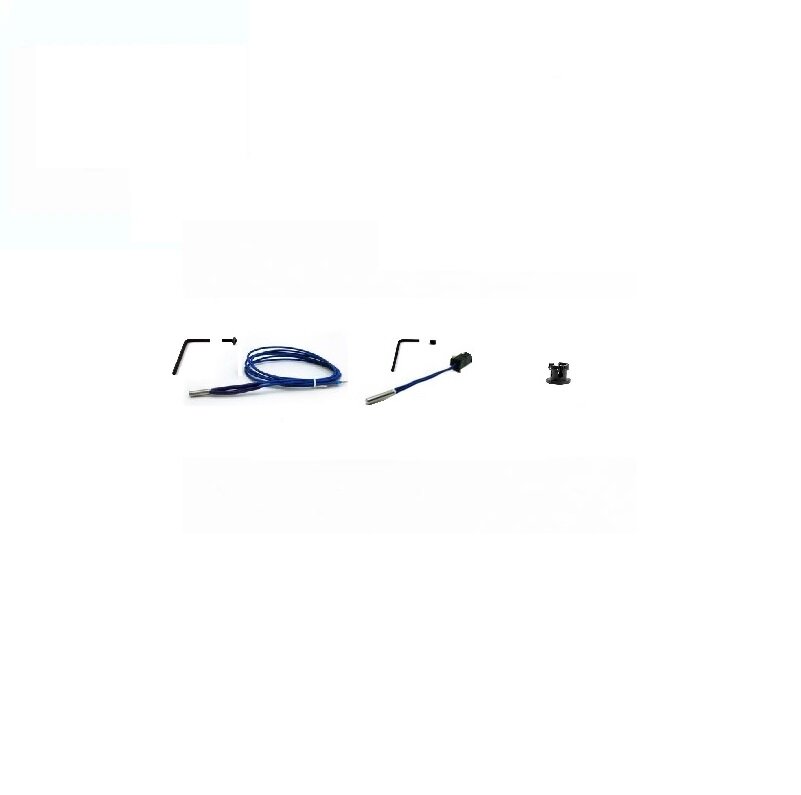

Hotend PTFE tubing

Option 1:

Advanced installation greatly reduces hotend jams

Option 2:

Typical installation, prone to hotend jams

Cut the ends of the PTFE tubing perfectly flat

Insert the PTFE tubing 5 cm into the heatsink

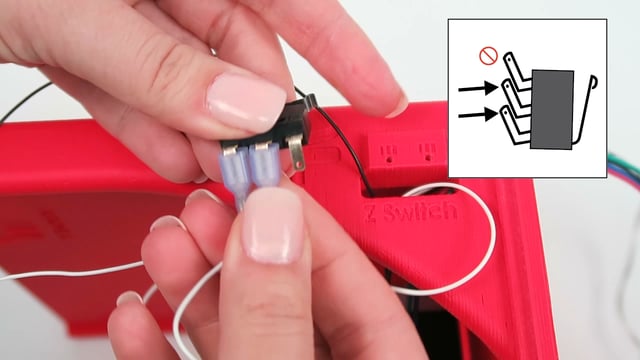

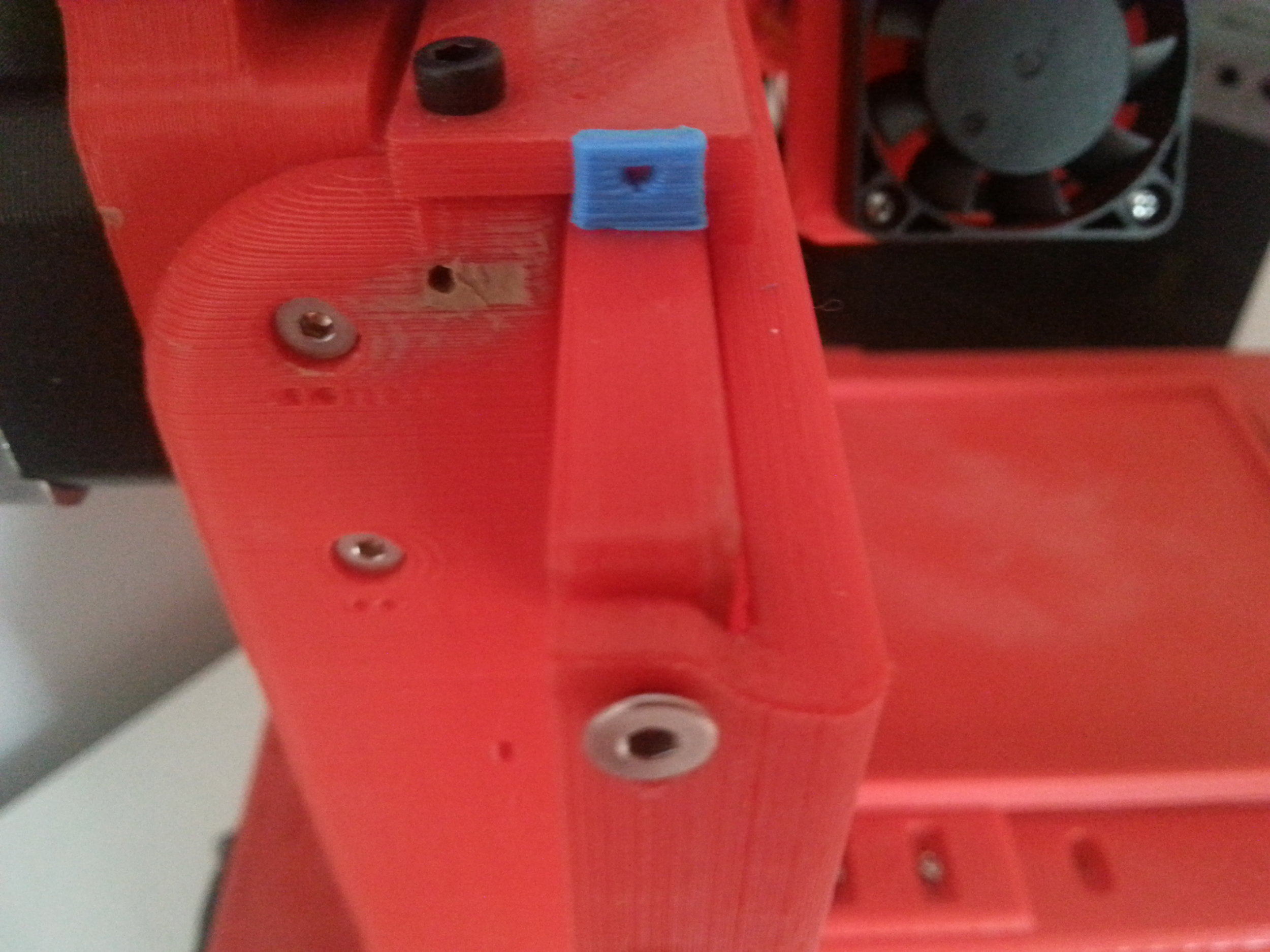

Lock into place the Bowden tube by lifting the black plastic coupler then insert the blue retaining clip

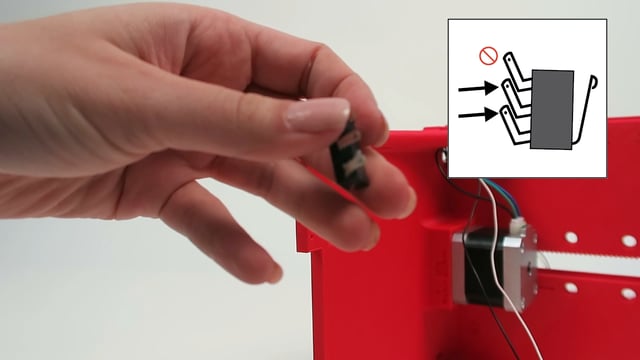

W

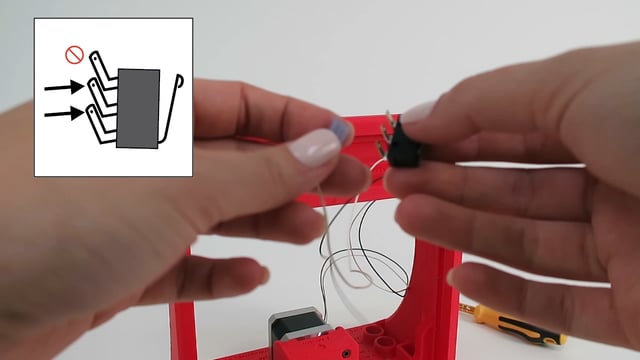

end switch preparation

Bend the pins in the right direction

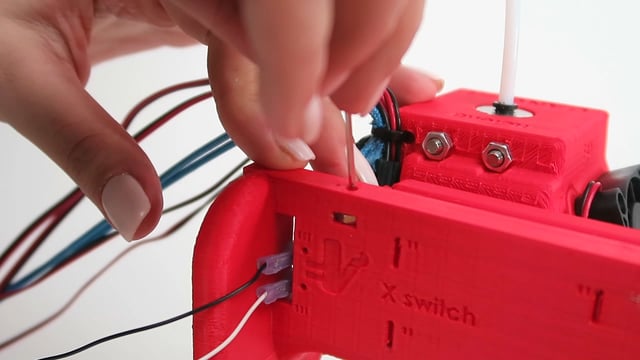

X

X axis end switch

Y

Mounting the hotend

Handle this part gently while installing it on the X axis rack

If it's difficult to screw the M3-12 bolts, do not force!

The nuts are not properly centered

Some plastic strings are still in the openings

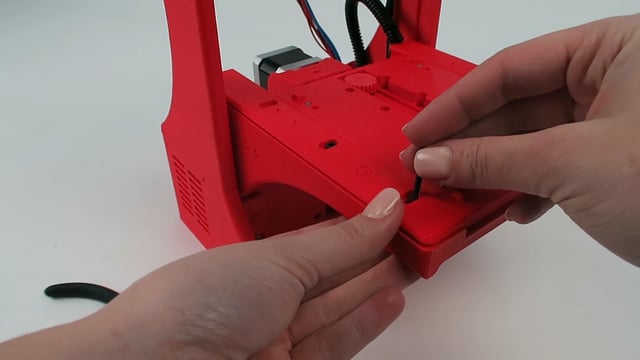

Z

rack holder preparation

Insert the M3 nuts with the sides parallel to the openings

Center the M3 nuts with a small allen key and a bolt

Spread plasticine to prevent the M3 nuts from falling out

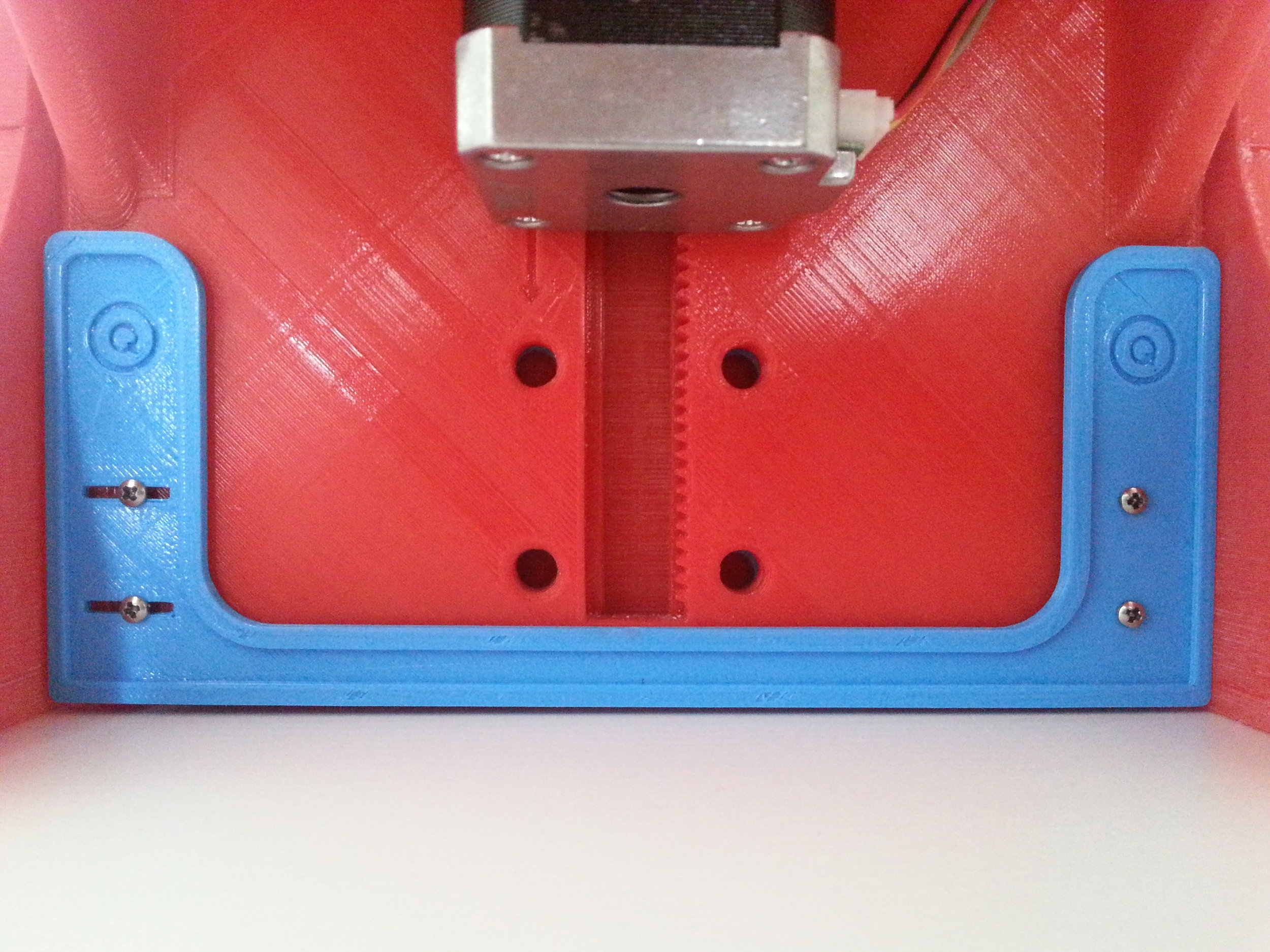

AA

rack holder installation

Install the 3 washers

Push back part I then fasten tight the M3-12 bolts

The X rack should move with ease, if not loosen up a bit the bolts

BB

Mounting the extruder

CC

leveling screws on the Y axis rack

Make sure the screws are flush up against the top surface

Once installed, the Y rack must close the Y end switch, if not you’ll need to add 1 x Phillips screw 3/8 in. at the tip

DD

Y AXIS RACK and PINION

install the Y axis rack with the teeth facing the same direction as shown in the video

Add 2 drops of glue inside the opening of the y axis gear

Align the flat side of the motor shaft with the flat side of the gear, hold the backside of the motor and push in the gear

Do not tap on the the motor, it will damage it

Allow the glue to dry for 5 minutes

To remove the gear, break off the head with pliers, remove the motor, then cut off the rest with cutters

EE

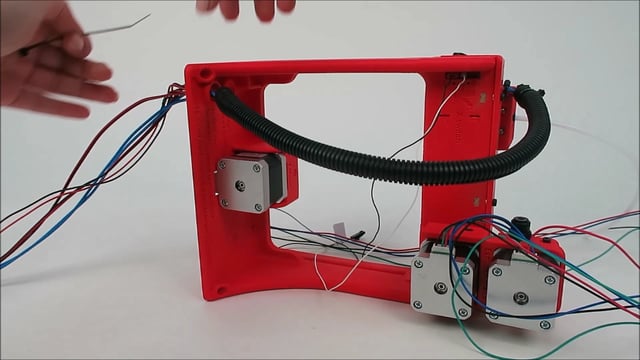

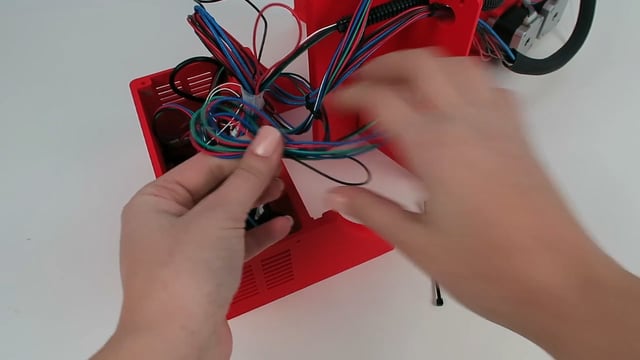

X, Y, Z and extruder motors wiring

FF

Y axis END SWITCH

GG

Z AXIS END SWITCH

HH

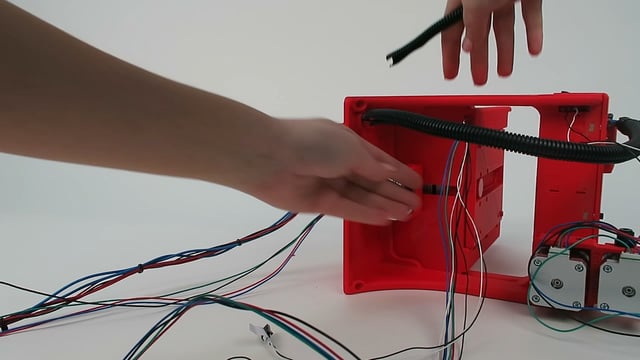

Cable management

Hotend, Fan 1 & 2

II

Cable management

Y motor, Y and Z end switches

JJ

Cable management

X and Extruder motors, X end switch

Scotch tape and tie raps

KK

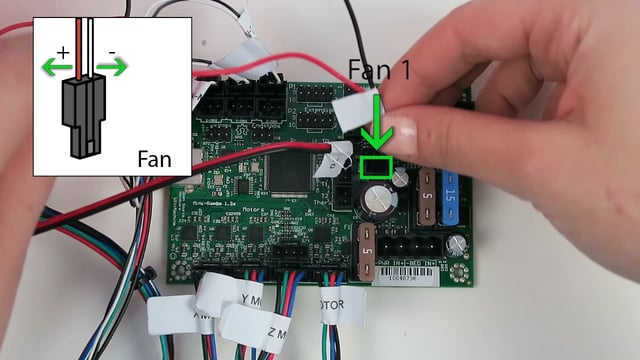

Microcontroller connections

Ground yourself before working with electronics

Follow the color code of the motor wiring, otherwise the motors will turn in the wrong direction

Press down tight all the connectors especially the motors

Non polarized connectors (you can reverse the wires)

Thermistor (T0)

X, Y and Z end switches

The heater cartridge (tagged as Extruder)

Polarized connectors (you can’t reverse the wires)

FAN 1 & 2 (red wire must be on the side of the USB)

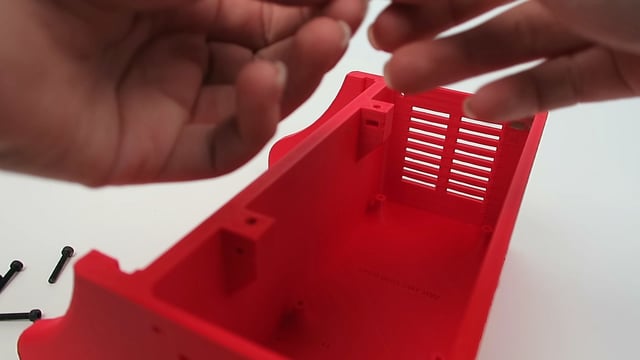

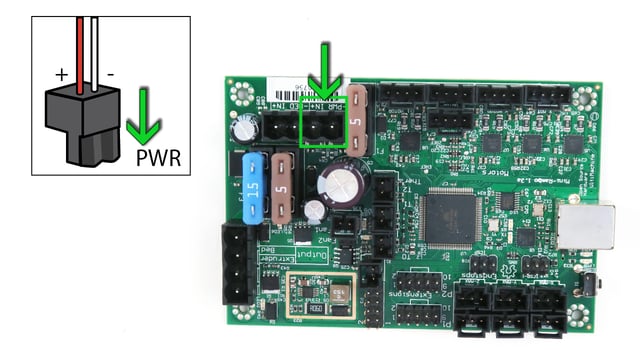

LL

Enclosure preparation

Insert the M3 nuts with the sides parallel to the openings

Center the M3 nuts with a small allen key and a bolt

Spread plasticine to prevent the M3 nuts from falling out

MM

Power wiring and USB panel mount

VERY IMPORTANT

Power supply is polarized, you must not reverse the wires

Fasten tight the nut of the DC power jack

NN

Mounting the microcontroller

Ground yourself before working with electronics

Power supply is polarized, you must not reverse the wires

The red wire is connected to the pin In+

The white wire is connected to the pin -PWR

OO

Cable management and printer assembly

If necessary insert a small Allen key to lock into place the M3 nuts while tightening the bolts

Tie rap both cables (HH & II) so they don't get in the way of the Y axis rack

PP

Z AXIS RACK & PINION

Add 2 drops of glue inside the opening of the z axis gear

Align the flat side of the motor shaft with the flat side of the gear, hold the backside of the motor and push in the gear

Do not tap on the the motor, it will damage it

Allow the glue to dry for 5 minutes

To remove the gear, break off the head with pliers, remove the motor, then cut off the rest with cutters

If the rack and pinion are slipping, minimize their gap

Unscrew the bolts by one turn, push the motor towards the rack, then retighten the bolts

Z axis lateral support

Position and screw the side support

If it’s too long, sand the sides

rr

Y axis side rail

Position the side rail while ensuring the Y rack moves with ease, then fasten the bolts and nuts

SS

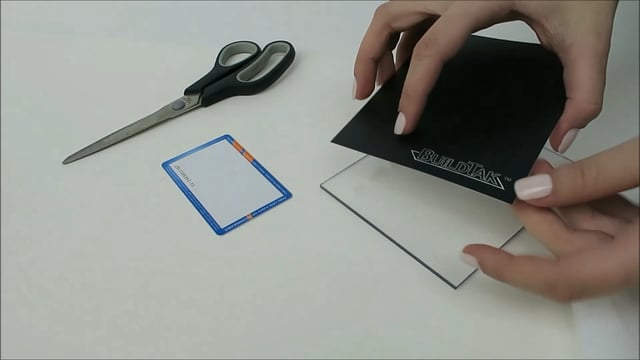

Printbed platform preparation

TT

Printbed preparation and assembly

It’s highly unlikely, but If the acrylic sheet is too big simply cut it a local hardware store

When tightening the bolt in place, make sure it does not slip under the acrylic sheet

UU

Printbed LATERAL SUPPORT

Use a folded paper to adjust the distance between the bracket & the print bed, then tighten the screws

VV

Y AXIS END switch cover

WW

Backside cable covering

XX

Z axis leveling screw

Before inserting the M3 nut, screw the M3-25 bolt from the top of the opening to widen the plastic hole

Insert the M3 nuts with the sides parallel to the openings

Although it is not shown in the video, you have to glue part T to the head of the M3-25 bolt

YY

PTFE tubing

ZZ

Z axis additional lateral support

Insert the red tube then install and fasten the screws

Ignore the V design & clear tubing in the video, these were older models but with the same assembly instructions

AAA

backside shim on the Z axis

Screw the shim on the backside of part C

Make sure the Z rack still moves with ease, if not reprint a thinner shim

BBB

shim on top of the X axis rack

CCC

LCD enclosure

Install the LCD inside the enclosure and fasten the screws

Disassemble the main body of the printer (see section OO)

Connect EXP1 and EXP2 to their respected terminals

Place the LCD cables on the side of the printer

Reassemble the main body of the printer (see section OO)

Fasten the backside of the enclosure

Install the knob

Important notice

DDD

filament Sharpener

Remove the blade from the pencil sharpener and install it on the 3D printed filament sharpener

very important step - Lubrication

Lubricate all moving parts by:

Adding and rubbing a few drops of good quality sewing machine oil meaning non-staining and non-gumming

Or, adding and rubbing a thin layer of Vaseline